Golf Course Maintenance System

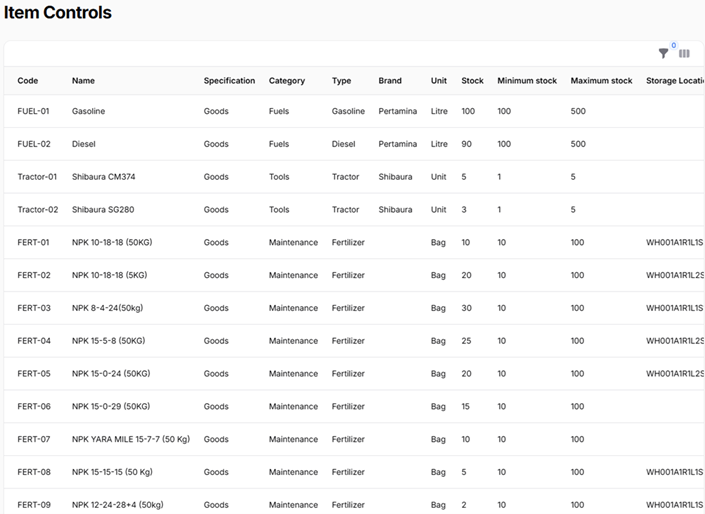

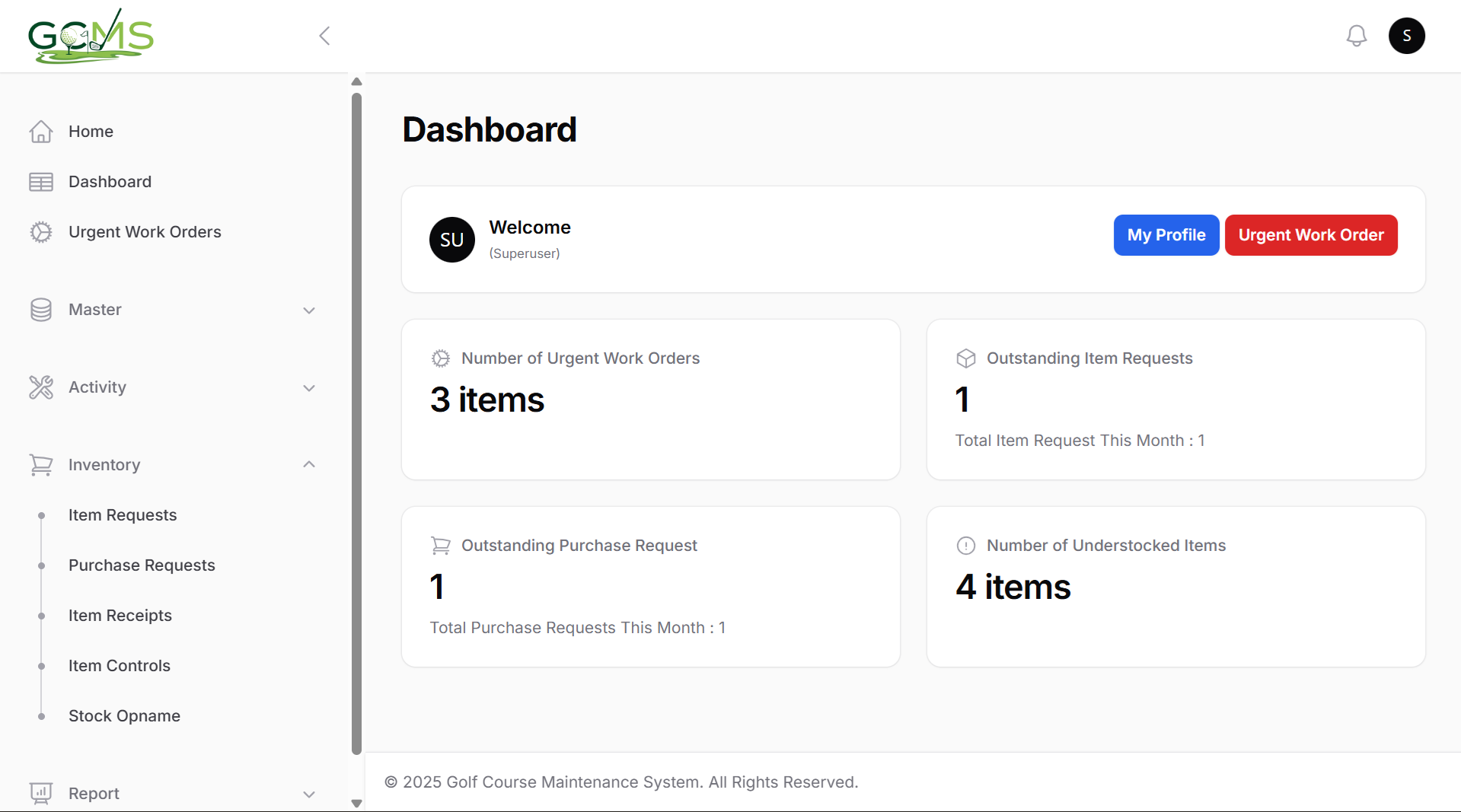

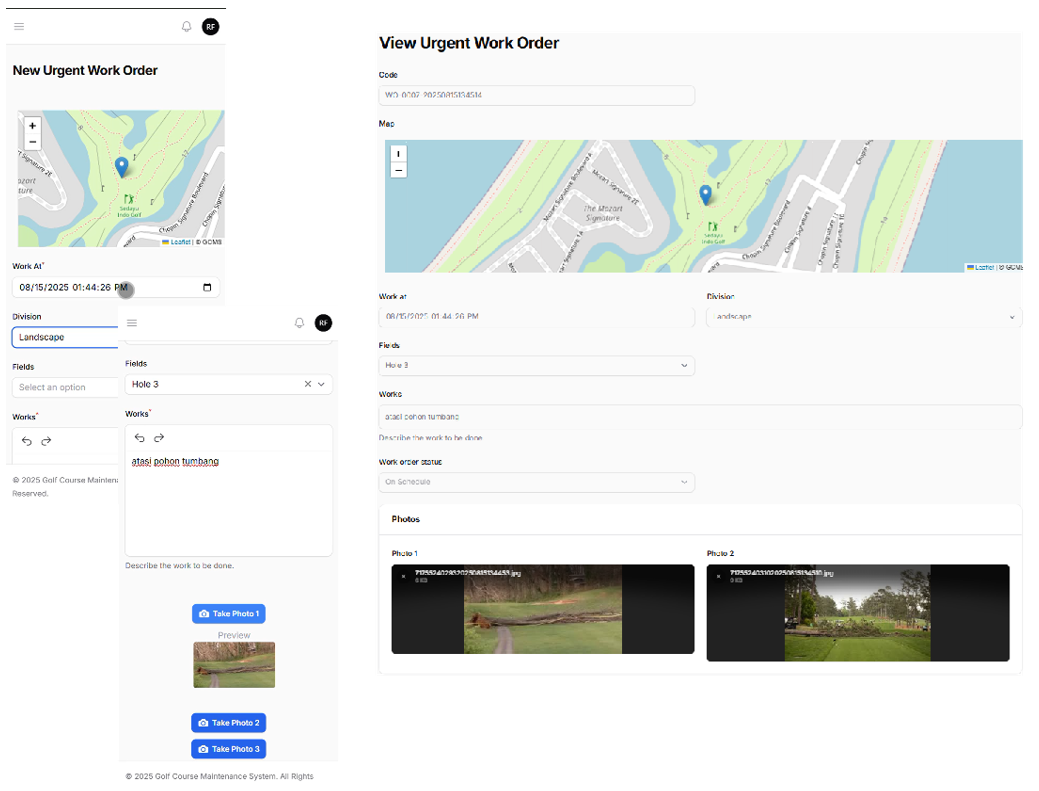

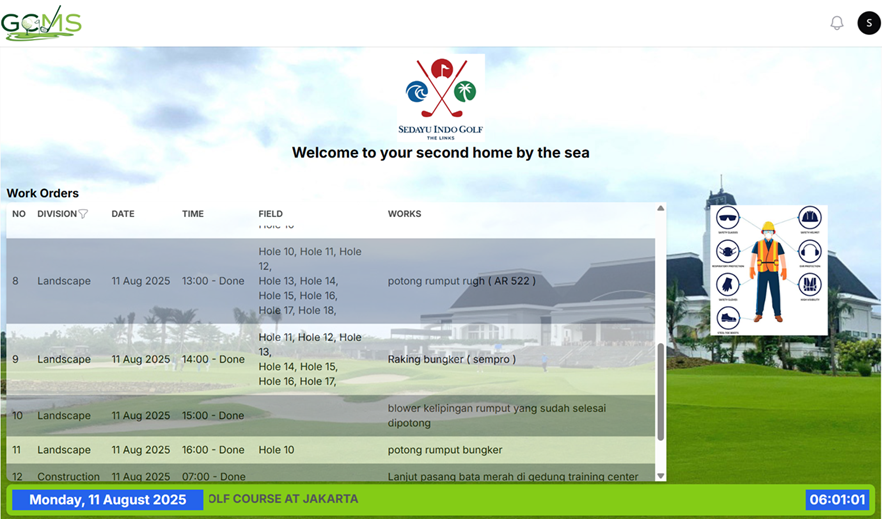

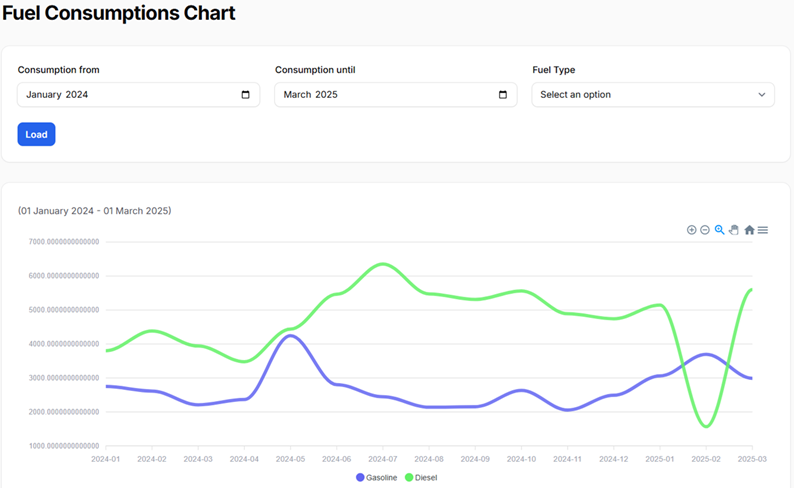

An integrated system built to support daily operational needs and maintenance activities on a golf course. GCMS helps streamline inventory management, equipment tracking, fuel monitoring, and work order processing to ensure efficient, well-documented, and reliable maintenance operations.

Features

Benefits of Using GCMS